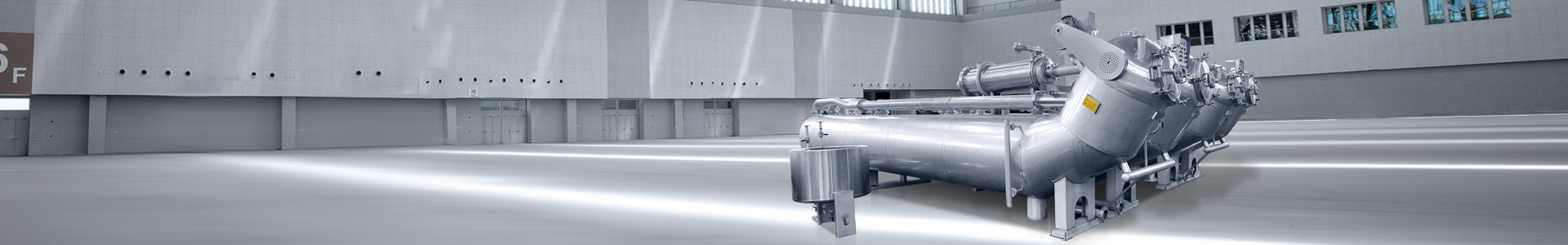

Y5-1500 Hank Yarn Dyeing Machine

Technical data:

The maximum operating temperature of 100℃

Heating Time:20℃-100℃(about 30minutes,steam pressure is 0.5Mpa)

Cooling Time:100℃-80℃(about 15minutes,cooling water pressure is 0.3Mpa)

Product Introduction

Product characteristics:

1.Fit for the hank yarn of various materials,such as wool,acrylic fibre,staple rayon,hemp,cotton and blended yarn.

2.Filling yarn once can make the processes of extrusion,refining,bleaching,dyeing and softening.

3.The tank connected with the dye is made of the SUS-316L(AISI-316L),a high degree of corrosion resistance of stainless steel,or SUS 321(AIS1-321),a high-quality stainless steel corrosion resistance.The stiffening plate is made of SUS-304(AISI-304)stainless steel,making the tank more durable.

4.Spindles are made of cold drawn tube with seamless precision,hard,with surface finish of 60 micron.

5.Indirect heating pipe line is installed on the top and in the bottom to ensure uniform temperature distribution dyes;direct heating pipe line is in the bottom.Meet all the requirements.

6.Circulating pump designed,four speed change to adapt to different types ofyarn dyeing and finishing.

7.Using precise time automatic controller will automatically switch the direction of impeller rotation,making dye circulating around from top to bottom.

8.Bottom plate installed to eliminate eddy current,uniform surface of the tank with cycle and to effectively prevent entanglement in the process.

9.Put sampler deep into the hank yarn,produced with the same color of skeins in a large jar or pot,and examine sample color in the process of dyeing yarn without stopping.

10.Dosing barrels have stirring,heating,feeding,recycling and cleaning devices to facilitate adjustment dye.550-800mm

11.Bath ratio:1:15-25

| Model | Capacity | Main Power | Dimension | Heightening | Weight | ||||||

| L2 | W2 | H2 | W1 | H1 | L1 | H2 | H1 | ||||

| kg | kw | mm | mm | mm | mm | mm | mm | mm | mm | kg | |

| Y10 | 4.5 | 1.1 | 1150 | 1200 | 1660 | 830 | 1520 | 430 | 190 | ||

| Y20 | 9 | 1.1 | 1190 | 1330 | 1660 | 1000 | 1520 | ,470 | 230 | ||

| Y50 | 23 | 1.5 | 1720 | 1300 | 1960 | 1220 | 1550 | 960 | 550 | ||

| Y100 | 45 | 2.2 | 2380 | 1910 | 2070 | 1330 | 1510 | 1590 | 750 | ||

| Y150 | 70 | 3 | 2530 | 2040 | 2060 | 1450 | 1630 | 1750 | 900 | ||

| Y200 | 90 | 3 | 2800 | 2180 | 2110 | 1270 | 1680 | 1905 | 1000 | ||

| Y300 | 140 | 4 | 2760 | 2160 | 3010 | 1460 | 2530 | 1750 | 1700 | ||

| Y400 | 185 | 5.5 | 2930 | 2350 | 3130 | 1510 | 2540 | 1915 | 3390 | 2800 | 1900 |

| Y600 | 275 | 7.5 | 3400 | 2770 | 3150 | 1910 | 2540 | 2380 | 3510 | 2900 | 2200 |

| Y800 | 360 | 11 | 3450 | 3270 | 3210 | 2120 | 2640 | 2380 | 3570 | 2900 | 2500 |

| Y1000 | 455 | 11 | 3680 | 3500 | 3210 | 2230 | 2640 | 2625 | 3570 | 2900 | 2700 |

| Y1200 | 535 | 11 | 4080 | 3500 | 3350 | 2230 | 2780 | 3065 | 3500 | ||

Note: the above parameters are for reference only

1)machine body

2)sampling device

3)hank

4)paint bucket

5)pai cooling water valve

6)steam trap

7)plus drum drainage valve

8)feeding pump

9)feeding valve

10)main pump impeller

11)drain valve

12)pulley

13)water intake valves

14)progressive cooling water valve

15)directly into the heating steam valve

16)indirect heat into steam valve

17)thermometer

18)orifice

19)overflow tube

20)level gauge