GR202 Series High Temperature High Pressure Dyeing Machine

Main Features:

★Temperature controller specially designed for dying machine.

★Storage of 120 dyeing programs and 120 steps are possible.

★Temperature curve,step and output may be simultaneously displayed.

★Control over temperature,material loading,speed and PH values.

★Automatic PID parameter tuning.

★Water inflow,water drain,water rinsing amount can be controlled according to different dyeing requirements.

★Parallel function:simultaneously control multi----program operation to reduce time of dyeing process.

Product Introduction

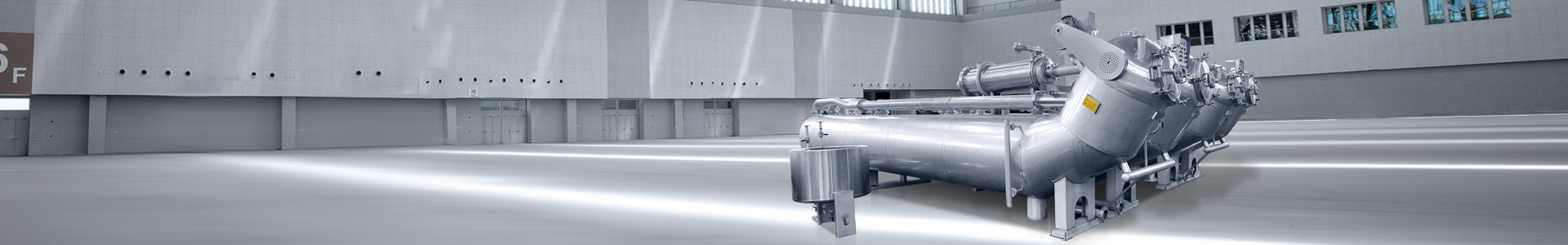

GR202 Series High Temperature High Pressure Dyeing Machine

GR202 Series High Temperature High Pressure Dyeing Machine is mainly designed for the application of dyeing,boiling off,bleaching,and water washing,etc.working procedure for hank yarn,bobbin or scattered fibre.

Machine type:Vertical cylinder type

Capacity:vary from 1kg to 1000kg

Working temperature:130℃

Max working pressure:0.4Mpa

Both ratio:1:7-9

Automatic computer controlled system and low maintainance efficiency

Heat exchanging method:Adopt coil type heat exchanger,which can be used for heating,and also can be used for cooling.

Heat exchanging speed:When the heating steam pressure is 0.4Mpa,40minutes will be required for the liquid inside the dyeing beck raising from 20℃ to 130℃.When the cooling water pressure is 0.3Mpa and the water temperature is 20℃,40 minutes will be required for the liquid inside the dyeing beck lowering from 130℃ to 80℃.

Recycling method of dyeing liquid:The positive and negative recycling of dyeing liquid will be adjusted by the cylinder through the switching device inside the cenrifugal pump.

Sealing method of boiler body:Adopt self-sealing type rubber adhesive tape.The working pressure inside the boiler will make the rubber adhesive tapeclosely attaching to the flange connoid surface of the boiler mouth so as to reaize the sealing or air-jacking target.

Opening method of boiler cover:Firstly open the safety insurance air valve to release the pressure inside the boiler.When there is no air exhausted from the exhaust valve and the reading of pressure gauge is zero,withdraw the wrench handle,open the clamping hoop to remove the flange and then open the cover with drag weight,the cover will be closed.

| Model | GR202-20 | GR202-43 | GR202-50 | GR202-60 | GR202-90 | GR202-120 | GR202-140 | GR202-166 | GR202-186 |

| Capacity(kg) | 5 | 15 | 30 | 50 | 100 | 300 | 500 | 750 | 1200 |

| Kier diameter (mm) | 200 | 430 | 500 | 600 | 900 | 1200 | 1400 | 1660 | 1860 |

| Main pump power(kw) | 4 | 5.5 | 7.5 | 11 | 18.5 | 30 | 37 | 55 | 110 |

| Size (mm) | 1100*550 *1400 | 1500*600 *2000 | 1800*850 *2500 | 2300*950 *2700 | 2600*1200 *2900 | 2900*1450 *3000 | 3000*1650 *3200 | 3200*1780 *3400 | 3650*1950 *4500 |