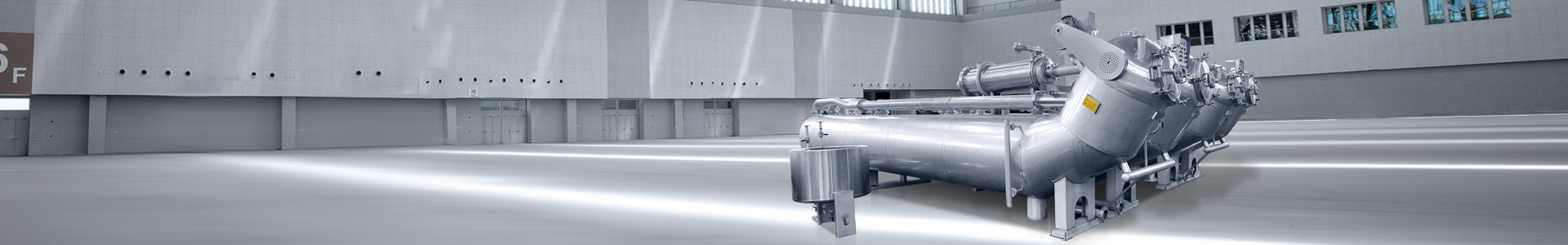

BGD energy-saving and environment-friendly cage-type garmentdyeing machine

The maximum pressure of the heater is:0.7Mpa.

The maximum temperature of the dyeing cylinder:98℃

Heating rate:about 5℃/min (based on 0.7 Mpa saturated steam pressure).

Cooling rate:about 3℃/min (based on 25℃ 0.3Mpa cooling water pressure).

The maximum speed of the cage:20 rev/min.

Power (KW)and dimensions

Product Introduction

Technical characteristics

★The BGD series of seamless underwear dyeing machines are made with imported Italian technology and improved.This model is suitable for seamless underwear,socks,cotton,nylon,spandex,Tencel,microfiber,viscose and blended fabrics.It can be bleached,scoured,dyed,washed and post-treated in one cylinder.

★The novel design of the cage makes the dyed object not easy to be deformed,and the load is large,the degree of automation is high,the operation is convenient,one person can watch multiple machines,reduce labor intensity,improve work efficiency,and have good dyeing quality.

★The water flow is externally circulated to make the dye liquor more evenly stirred.

★The external heater is used for heating,the dyeing liquid is heated evenly,the heating speed is fast,and the dyeing time is saved.When cooling,the heat energy in the dyeing liquid can be extracted,the water can be heated,and the hot water can be stored for the next tank dyeing or washing,which can save energy and shorten the entire process time.

★A specially designed sampling device safely samples without opening the cylinder head.

★Variable frequency control cage motor,can choose the appropriate speed according to different fabrics.

★Compared with the conventional dyeing machine,the dyeing cost is greatly saved.Because the machine cage is designed to be three grids,the water consumption is less,the bath ratio is 1:8,and the environmental pollution is reduced.This machine is also an inevitable trend for widespread use in the future.

| Model | Kg Load | Cage power | Main pump power | Pump power | Stirring power | Dimensions |

| AGD-3 | 3 | 1.1 | 1.5 | 1.5 | 0.025 | 1750x1650x1200 |

| AGD-10 | 10 | 2.2 | 1.5 | 1.5 | 0.75 | 1600x1100x1900 |

| AGD-25 | 25 | 2.2 | 1.5 | 1.5 | 0.75 | 1400x 1360x1950 |

| AGD-50 | 50 | 3.0 | 2.2 | 1.5 | 0.75 | 2300x2750x2260 |

| AGD-100 | 100 | 4.0 | 2.2 | 1.5 | 0.75 | 2600x3100x2500 |

| AGD-200 | 200 | 5.5 | 3 | 1.5 | 1.1 | 3150x3980x3000 |